Successful Case Studies in Composite Repair Engineering

- josephimo

- Dec 15, 2025

- 4 min read

Composite materials have revolutionized various industries, offering lightweight, high-strength solutions that traditional materials often cannot match. However, like any material, composites can suffer damage over time. This is where composite repair engineering comes into play, providing innovative solutions to restore the integrity and functionality of composite structures. In this blog post, we will explore successful case studies in composite repair engineering, highlighting the techniques used, the challenges faced, and the outcomes achieved.

Understanding Composite Materials

Before diving into the case studies, it's essential to understand what composite materials are and why they are used. Composites are made from two or more constituent materials with significantly different physical or chemical properties. The resulting material has characteristics that are superior to those of the individual components.

Common Types of Composite Materials

Fiber-Reinforced Polymers (FRP): These are the most common composites, consisting of a polymer matrix reinforced with fibers, such as glass or carbon.

Metal Matrix Composites (MMC): These combine metal with another material, often to improve strength and reduce weight.

Ceramic Matrix Composites (CMC): These are designed to withstand high temperatures and are often used in aerospace applications.

Advantages of Composite Materials

Lightweight: Composites are significantly lighter than metals, making them ideal for applications where weight is a critical factor.

High Strength-to-Weight Ratio: Composites can provide superior strength without the added weight.

Corrosion Resistance: Many composites resist corrosion better than traditional materials, extending their lifespan.

Case Study 1: Repairing Aircraft Wings

Background

In the aerospace industry, the integrity of aircraft wings is paramount. A major airline faced a significant challenge when one of its aircraft sustained damage to its composite wing during routine maintenance. The damage was extensive, requiring a solution that would restore the wing's structural integrity without compromising safety.

Repair Techniques Used

The repair team employed a combination of advanced techniques, including:

Surface Preparation: The damaged area was meticulously cleaned and prepared to ensure proper adhesion of the repair materials.

Composite Patch Application: A pre-impregnated composite patch was applied to the damaged area. This patch was designed to bond seamlessly with the existing material.

Curing Process: The patch was cured using a controlled heat process to ensure optimal bonding and strength.

Outcome

The repair was completed within a week, allowing the aircraft to return to service promptly. Post-repair inspections confirmed that the wing met all safety standards, demonstrating the effectiveness of composite repair engineering in the aerospace sector.

Case Study 2: Marine Vessel Hull Repair

Background

A commercial fishing vessel experienced hull damage due to a collision with a submerged object. The hull was constructed from fiberglass-reinforced plastic (FRP), and the damage threatened the vessel's seaworthiness.

Repair Techniques Used

The repair process involved several key steps:

Damage Assessment: A thorough inspection was conducted to assess the extent of the damage and identify any underlying issues.

Core Replacement: The damaged core material was removed and replaced with a new, high-density foam core to restore structural integrity.

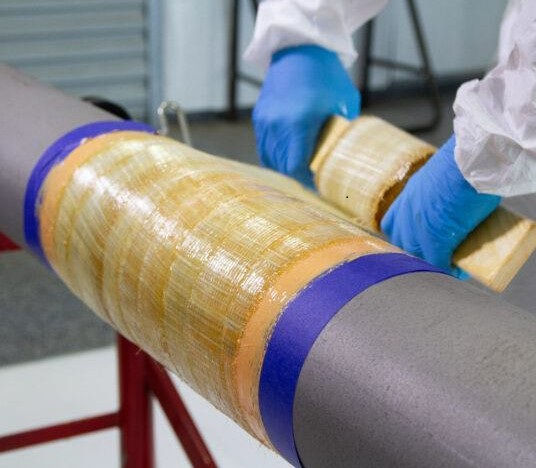

Layering Technique: Multiple layers of fiberglass cloth were applied, each saturated with resin, to build up the strength of the repair.

Finishing: The repaired area was sanded and painted to match the original hull, ensuring a seamless appearance.

Outcome

The vessel was back in operation within two weeks, and follow-up inspections indicated that the repair exceeded the original strength of the hull. This case highlights the effectiveness of composite repair techniques in the marine industry.

Case Study 3: Wind Turbine Blade Repair

Background

Wind energy is a growing sector, and the blades of wind turbines are often made from composite materials. A wind farm operator faced a challenge when one of its turbine blades sustained damage from lightning strikes, leading to a significant loss in energy production.

Repair Techniques Used

The repair team implemented the following strategies:

Damage Evaluation: Advanced non-destructive testing methods were used to evaluate the extent of the damage and identify any internal issues.

Resin Injection: A specialized resin was injected into the damaged areas to restore the blade's structural integrity.

Reinforcement: Additional layers of composite material were applied to reinforce the repaired sections.

Surface Finishing: The blade was finished with a protective coating to enhance durability against future environmental factors.

Outcome

The repair was completed in a matter of days, allowing the wind turbine to resume operation quickly. The repair not only restored functionality but also improved the blade's performance, showcasing the potential of composite repair engineering in renewable energy applications.

Challenges in Composite Repair Engineering

While composite repair engineering has proven effective in various applications, it is not without its challenges. Some common issues include:

Material Compatibility: Ensuring that the repair materials are compatible with the existing composite can be complex.

Curing Conditions: Achieving the right curing conditions is critical for the success of the repair.

Cost Considerations: High-quality repair materials and specialized labor can lead to increased costs.

Future Trends in Composite Repair Engineering

As technology advances, the field of composite repair engineering is evolving. Some trends to watch include:

Automation: The use of robotic systems for repairs can improve precision and reduce labor costs.

Advanced Materials: Research into new composite materials may lead to even stronger and more durable repairs.

Sustainability: The focus on environmentally friendly materials and processes is becoming increasingly important in the industry.

Conclusion

Composite repair engineering plays a crucial role in maintaining the integrity and functionality of composite structures across various industries. The case studies presented demonstrate the effectiveness of innovative repair techniques in aerospace, marine, and renewable energy applications. As technology continues to evolve, the potential for composite repair engineering will only expand, offering new solutions to old problems.

For those involved in industries that rely on composite materials, understanding these successful case studies can provide valuable insights into effective repair strategies. Whether you are facing a minor repair or a significant restoration project, the lessons learned from these cases can guide you toward successful outcomes.

Comments